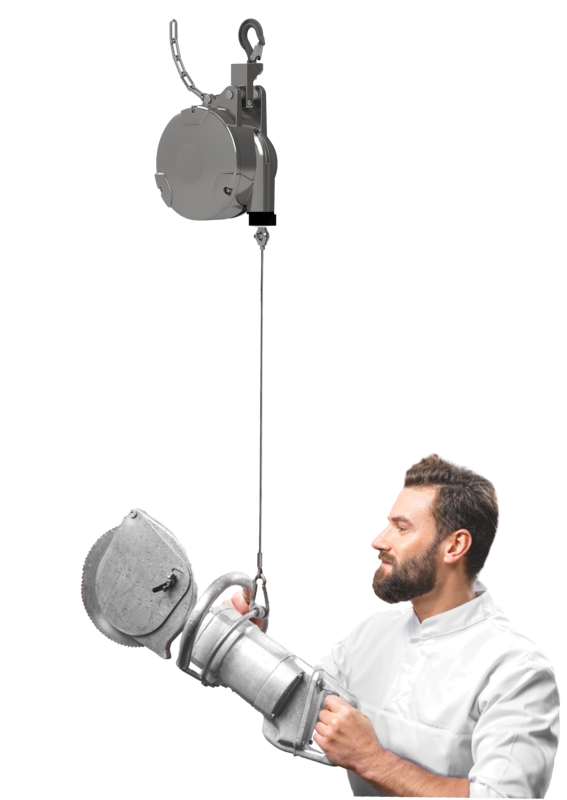

Thanks to the use of food-grade, NSF-compliant lubricants and rust-resistant materials, Kromer spring balancers (retractors) and weight balancers are ideal for use in humid work environments with stringent hygiene requirements. The proven basic principle of our products remains unchanged: heavy tools, such as saws used in meat processing, are ergonomically positioned and reliably available to the user at all times. This not only improves ergonomics but also optimizes workflow in production significantly.

In the demanding environment of the meat processing industry, efficiency and safety are of paramount importance. Spring Balancers and Balancers prove to be useful tools that offer a variety of advantages and improve operational workflows. One of the key benefits of using Spring Balancers and Balancers in meat processing facilities lies in their construction with aluminum and stainless materials. In environments where moisture is prevalent, conventional tools can fall victim to corrosion over time, affecting both durability and performance. Kromer Spring Balancers and Balancers, made from rust-resistant materials, not only ensure longevity but also maintain optimal functionality even under challenging working conditions.

Beyond their corrosion resistance, Kromer Balancers demonstrate exceptionally high balancing behavior. This feature is crucial for facilitating ergonomic work processes by enabling workers to operate machines and tools with minimal physical effort. The balancing behavior of these devices contributes to a smoother workflow, reduces worker strain, and enhances overall efficiency in meat processing tasks.

By compensating for the weight of tools and equipment, balancers minimize the risk of accidents caused by heavy loads. This not only protects the well-being of employees but also safeguards valuable equipment integrity and reduces the likelihood of injuries and damage in the meat processing environment. The implementation of spring balancers and weight balancers goes beyond safety; it also leads to a tangible increase in productivity. By reducing the physical strain on workers, these devices enable employees to perform their tasks with greater ease and speed. As a result, the meat processing industry experiences an overall boost in efficiency, leading to increased productivity and potentially higher output.

In summary, the introduction of spring balancers and weight balancers in the meat processing industry offers a multifaceted range of benefits. From their stainless construction suited for humid environments to their high balancing behavior that facilitates ergonomic work steps, these devices contribute to a safer, more efficient, and ultimately more productive workplace. Investing in spring balancers and balancers is not only a strategic decision for equipment longevity but also a commitment to the well-being and productivity of the workforce.