Our high-quality air hose retractors of type 7211 and 7221 are available with a compressed air hose measuring 9x13 mm or 11x16 mm. In addition, we also offer an air hose balancer type 7223 with a permanently integrated air hose measuring 5x8 mm. All our hose spring balancers are designed for a maximum operating pressure of 10 bar and can therefore be combined with all common pneumatic tools in assembly.

Our high-quality Air-Hose Balancers for ergonomic handling of pneumatic tools are durable, manufactured in accordance with DIN 15112, and tested for safety by an external testing agency. That is why our hose spring balancers for compressed air tools bear the GS seal of approval (tested for safety). By using Hose Retractors and Hose Balancers at assembly workstations, work can be carried out more safely, more precisely, and over a longer period of time without a drop in performance. Kromer Air-hose Edition covers a load range between 0 and 12 kg.

For the Air hose Retractor 7211 and 7221, we also offer an automatic arresting system that stops the retraction force and enables locking the attached load at a predefined position. Especially for repetitive work steps, the automatic locking system further increases ergonomics at the workplace.

Kromer's high-quality Air-hose Retractors and Balancers are available in different configurations. You can choose from the entry-level model designed for pneumatic small tools, optimized variants with guided spiral hoses, and particularly robust devices designed for continuous heavy-duty use. Depending on the model, our air spring balancers can handle loads ranging from 0.4 to 14 kilograms. The maximum cable extension varies between 0.8 and 3 meters. Choose according to your specific needs. With a consistent air throughput of 900 l/min at a maximum pressure of 10 bar, all our models meet the practical requirements.

Air hose Spring Balancers, Type 7211 and Type 7221, are optionally available with automatic locking (Type 7212 and Type 7222). This feature allows for a premature stop at the desired position during slow retraction. This function proves highly beneficial for certain tasks.

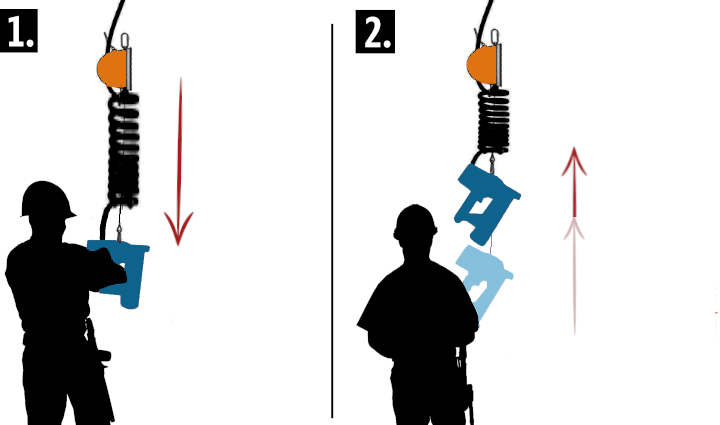

Air-Hose Spring Balancers, also known Balancers with compressed air hoses, are innovative tool supports specifically designed for the application of pneumatic tools. These devices offer a range of benefits that enhance operations in workshops and production environments. The primary advantage of hose spring balancers lies in their ability to optimize the handling of pneumatic tools. By integrating a compressed air hose into the spring balance mechanism, tools not only become lighter and more flexible but can also be effortlessly moved and precisely positioned. This results in a significant reduction of physical strain on operators and enhances overall work performance.

Another crucial benefit is the organization and cleanliness they bring to the workplace. The compressed air hose is securely stored in the spring balancer, preventing tripping hazards and maintaining a tidy work area. This not only promotes safety but also contributes to an efficient working environment. Hose spring balancers also contribute to prolonging the lifespan of compressed air hoses by protecting them from wear, kinks, or damage. Securely storing the hose preserves its integrity, thereby improving the overall durability of the tool equipment.

In summary, hose spring balancers offer an ergonomic solution for working with pneumatic tools. They enhance mobility, minimize operator strain, promote workplace safety, and contribute to the maintenance of tool equipment. This makes them an indispensable tool in environments where pneumatic tools are regularly employed.